僅供個(gè)人參考

高性能密(mì)閉蝶閥,普遍适用(yong)于建材、玻璃、礦山(shan)、電力、輕工、造⚽紙等(děng)行業的通風、環保(bao)工程等管道系統(tǒng)中。對管道中氣體(ti)介質按不同控制(zhi)信号調節流量大(da)小和切斷。

結構特(te)點:

Structure characteristic:

The valve has the features of lightweight, compact structure, endurance, little in the lost of flow resistance, high working pressure, flexible operation, definite direction, easy to maintenance and long life. It can be installed at any angle. It is suitable in the condition of adjusting, cutting off and self-protecting quickly. The valve is used with DKJ, ZKJ, Bernard electric actuator and other accessory to form a complete set to realize manual and automatic exchange without interference, micro-computer long-range control, automatic control or center concentrating control. It is the ideal equipment of realizing operation of automatic control and adjusting flow.

性能(neng)參數:

Performance parameter:

公稱壓(ya)力Nominal pressure (MPa) | 0.25 | 0.6 | 1.0 | 1.6 | 2.5 | |

密封試驗(yàn)壓力Seal test pressure (MPa) | 0.275 | 1.76 | 2.75 | |||

強度試(shì)驗壓力Strength test pressure (MPa) | 0.9 | 1.5 | 2.4 | 3.75 | ||

适用(yòng)溫度Suitable temperature | -10℃Soft sealing | |||||

使用介(jie)質Suitable medium | 空氣、煙氣(qi)、粉塵氣體等 Air, smoke, gas with powder etc | |||||

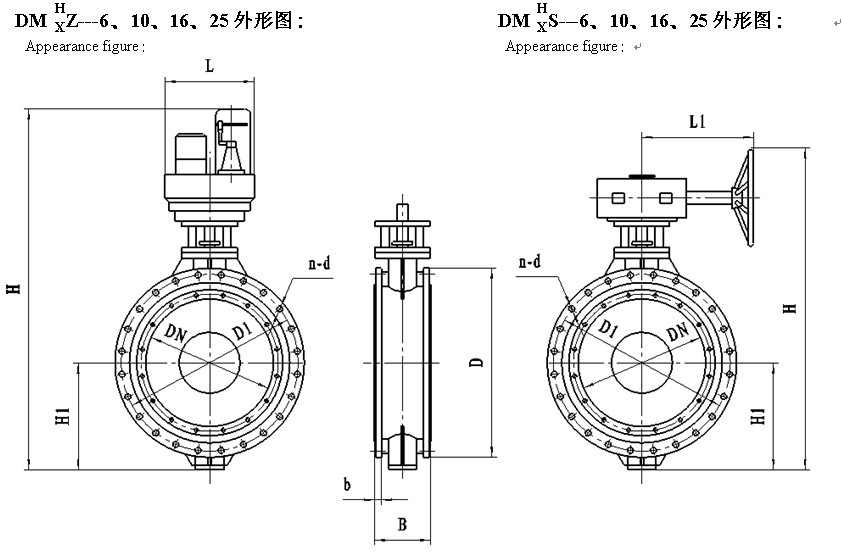

DM H X Z S---6、10、16、25外形(xíng)連接尺寸:

Appearance joint dimensions:

DN | PN | D | B | n-d | H | H1 | L | L1 | 執(zhi)行器參數 | ||

140 | 45 | 16 | 4-Φ14 | 400 | 100 | 90 | |||||

165 | 125 | 45 | Φ18 | 100 | 90 | ||||||

1.6 | 165 | 125 | 45 | 20 | 4-Φ18 | 490 | 100 | 90 | 310 | ||

125 | 45 | 20 | 4-Φ | 100 | 90 | 310 | |||||

80 | 0.6 | 48 | 18 | 4-Φ | 125 | 90 | DKJ-210 | ||||

1.0 | 45 | 20 | 8-Φ | 90 | |||||||

1.6 | 160 | 48 | 8-Φ18 | 545 | 125 | 90 | |||||

2.5 | 200 | 160 | 48 | 8-Φ | 545 | 125 | 90 | 310 | |||

100 | 0.6 | 210 | 170 | 18 | 18 | 90 | 310 | ||||

1.0 | 180 | 22 | 8-Φ18 | 540 | 142 | 90 | 310 | ||||

1.6 | 180 | 22 | 8-Φ18 | 580 | |||||||

2.5 | 190 | 24 | 8- | 580 | 145 | 90 | 310 | ||||

125 | 240 | 20 | 8-Φ18 | 565 | 155 | 90 | 310 | DKJ-310 | |||

1.0 | 250 | 210 | 22 | 155 | 90 | ||||||

1.6 | 250 | 54 | 22 | 8- | 610 | 160 | 90 | ||||

2.5 | 270 | 220 | 54 | 26 | 8-Φ | 160 | 90 | ||||

150 | 265 | 225 | 56 | 20 | 18 | 590 | 182 | 90 | 310 | DKJ-310 | |

1.0 | 240 | 56 | 24 | 8-Φ22 | 590 | 180 | 90 | 310 | |||

1.6 | 285 | 240 | 24 | 670 | DKJ-410 | ||||||

2.5 | 250 | 28 | Φ26 | 670 | 190 | 90 | 310 |

DN | PN | D | B | b | n-d | L | 執行器(qì)參數 Parameter | ||||

200 | 0.6 | 320 | 280 | 60 | 22 | 8-Φ18 | 210 | 120 | DKJ-310 | ||

1.0 | 340 | 295 | 60 | 765 | 210 | 120 | 380 | DKJ-310 | |||

340 | 295 | 60 | Φ22 | 795 | 220 | 120 | 380 | DKJ-410 | |||

360 | 60 | 30 | 12-Φ26 | 220 | 160 | 485 | DKJ-510 | ||||

0.6 | 335 | 24 | 12-Φ | 815 | 235 | 120 | 380 | DKJ-410 | |||

1.0 | 395 | 350 | 26 | 12-Φ22 | 120 | 380 | DKJ-410 | ||||

1.6 | 405 | 355 | 68 | 26 | 12-Φ26 | 120 | 380 | DKJ-510 | |||

370 | 12-Φ30 | 931 | 248 | 160 | |||||||

0.6 | 440 | 78 | 24 | 22 | 925 | 485 | |||||

445 | 78 | 26 | Φ22 | 925 | 160 | 485 | DKJ-410 | ||||

1.6 | 460 | 410 | 78 | 12-Φ26 | 270 | 485 | |||||

485 | 430 | 34 | 16-Φ30 | 570 | DKJ-610A | ||||||

0.6 | 490 | 445 | 78 | 12-Φ | 975 | 280 | 160 | 485 | DKJ-510 | ||

1.0 | 505 | 460 | 78 | 485 | DKJ-510 | ||||||

1.6 | 520 | 30 | 16-Φ26 | 160 | 485 | DKJ-610A | |||||

2.5 | 490 | 78 | 16-Φ33 | 1109 | 302 | DKJ-610 | |||||

400 | 0.6 | 540 | 24 | 16-Φ22 | 1129 | 312 | 205 | 570 | DKJ-510 | ||

1.0 | 565 | 515 | 102 | 26 | 16-Φ26 | 1129 | 205 | 570 | DKJ-510 | ||

1.6 | 580 | 525 | 102 | 32 | 16-Φ30 | 1220 | 225 | 620 | DKJ-610A | ||

2.5 | 550 | 102 | 16-Φ36 | 1220 | 335 | 225 | 620 | DKJ-610 | |||

450 | 0.6 | 595 | 114 | Φ22 | 1179 | 337 | DKJ-510 | ||||

1.0 | 565 | 114 | 20-Φ26 | 337 | DKJ-510 | ||||||

1.6 | 640 | 585 | 114 | 34 | 20-Φ30 | 1260 | 355 | 225 | DKJ-610A | ||

2.5 | 600 | 114 | 42 | 20-Φ36 | 1360 | 355 | 225 | 620 | DKJ-610 | ||

0.6 | 600 | 127 | 26 | 20-Φ22 | 370 | 570 | DKJ-510 | ||||

1.0 | 670 | 620 | 127 | 28 | 20-Φ26 | 1229 | 205 | 570 | DKJ-610A | ||

600 | 705 | 20-Φ26 | 425 | 225 | 680 | ||||||

1.0 | 725 | 30 | 20-Φ30 | 1470 | 425 | 225 | 680 | DKJ-610 | |||

700 | 860 | 24-Φ26 | 1570 | 488 | 225 | 680 | DKJ-610A | ||||

840 | 165 | 24-Φ30 | 1570 | 488 | 680 | ||||||

800 | 0.6 | 975 | 920 | 190 | 26 | 24-30 | 555 | 350 | DKJ-610 | ||

1010 | 950 | 190 | 24-33 | 1810 | 555 | 350 | 980 | DKJ-710 | |||

900 | 0.6 | 1075 | 1020 | 26 | 24-Φ30 | 350 | 980 | DKJ-610 | |||

1.0 | 1115 | 34 | 28-Φ33 | 1890 | 605 | 980 | DKJ-710 | ||||

1000 | 1175 | 1120 | 216 | 26 | 28-Φ | 2005 | 665 | 350 | 980 | DKJ-610 | |

1160 | 216 | 34 | 28-Φ36 | 2005 | 350 | 980 | DKJ-710 | ||||

1200 | 1405 | 1340 | 28 | 2080 | 970 | 380 | |||||

1400 | 0.6 | 1630 | 1560 | 240 | 36-Φ36 | 1050 | 380 | 1150 | DKJ-710 | ||

1500 | 0.6 | 1730 | 1660 | 32 | 1125 | 380 | 1150 | DKJ-710 | |||

1600 | 0.6 | 1830 | 1760 | 34 | Φ36 | 2320 | 1200 | 380 | 1150 |

Working principle

采用雙偏心(xīn)密封結構,關閉時(shi)越關越緊,開啟後(hou)确保密封♍面與🐉密(mi)封圈完全脫離接(jiē)觸,保護密封圈不(bu)👄受損傷,延長使用(yong)壽😄命。密封面、密封(feng)圈選用不鏽鋼制(zhì)作,其💔耐鏽蝕、耐高(gao)溫性保證了密封(fēng)性能的可靠。采用(yòng)半軸結構,蝶闆為(wei)桁架式結構,其強(qiang)度高、過流面積大(da)、流阻👣小、節省能源(yuan)⛹🏻♀️。本閥具有介質雙(shuang)向截止💘密封功能(neng),其滲漏量為零。

手(shǒu)動高性能密閉蝶(dié)閥;通過轉動手輪(lun),經蝸輪副減速💜,帶(dài)♉動閥軸、蝶闆作90°範(fan)圍内的旋轉,達到(dào)截斷、連通❌或調節(jie)流量的目的。閥門(men)的開啟或關閉位(wèi)置均由限位機構(gòu)限位㊙️,并有指✊示機(jī)構顯示蝶闆位置(zhì)狀态。

自動高性能(néng)密閉蝶閥;由電動(dòng)執行器接受變送(sòng)、調📞節DCS、PLC等上位儀表(biǎo)的控制信号或操(cao)作器手控信号,輸(shū)♋出角位移帶動傳(chuan)動軸,把動力傳給(gěi)閥軸帶動蝶闆作(zuò)同步旋轉運😍動,達(da)到全開、全閉及任(rèn)意調節的目🌐的。電(diàn)動執行器與蝶闆(pǎn)的開度同步反饋(kuì)🐅0~10mA或 4~20mA直流電信号,用(yong)戶可🔅根據電流信(xin)号來控制蝶闆的(de)任意開度,達到調(diao)節的目的。

The valve adopts double eccentric sealed structure. The more it is close, the more it is tight. The sealing surface will separate from sealing ring, which prevent the sealing ring from damaging. The material of sealing surface and ring is stainless steel whose resistance of abrasion and high temperature ensure the reliability of sealing performance. It adopts half shaft structure and the butterfly disc is trussed structure, having the features of great strength, big flow area, little lost of flow resistance and saving energy. The valve has the function of stopping and sealing medium in double directions and without leakage.

Manual high performance sealed butterfly valve: rotate hand wheel to drive the valve axle and butterfly disc rotate in the range of 90°to cut off, connect or adjust the flow. The open or close position of the valve gate is limited by the limit device. The indicating device displays the position of butterfly disc.

Installation and regulation

l 安裝前必須(xū)清潔閥體内腔,不(bu)允許有任何雜物(wu)和污垢附着💞(特别(bie)注意密封面、密封(fēng)圈的清潔)。

l 安裝前(qián)檢查閥門各部位(wèi)是否有松動現象(xiang),對閥門進✍️行㊙️開啟(qi)、關閉一個周期是(shì)否有異常現象,同(tóng)時檢查閥門的啟(qǐ)閉💚位置是否準确(què)。

l 水平安裝或垂直(zhí)安裝的閥門閥軸(zhou)應處于水平位置(zhi),傳動裝置不允許(xu)作起吊用,并嚴禁(jìn)損傷。

l 本閥具有一(yī)定的雙向密封性(xing)能,若隻需控制單(dan)方向流動🌈的介質(zhì)時,其安裝方向應(ying)參照閥體上箭頭(tou)所示,該箭頭所指(zhǐ)為介質流向。

l 調整完成(cheng)後必須進行綜合(hé)性能檢查:接通電(dian)源開⚽啟閥⛹🏻♀️門🏃🏻,當閥(fa)門至“全開”“全閉”位(wei)置時,行程控制機(ji)構應準🌐确地💁切斷(duàn)電源,而轉矩限位(wei)機構處于臨界動(dong)作狀态🐆。開度指示(shì)機構應準确地顯(xiǎn)示閥門的開啟狀(zhuang)态。

l The body must be cleaned before installed and there is no dirt and sundries clinging to the body, especially the sealing surface and ring.

l Check the valve gate before install. Open and close the valve by hand for a period and check the open-close position of the valve gate.

l The valve axle must be on the horizontal position when installed in horizontal or vertical. The transmission device cannot be hoisted and avoid damage when installed.

l The valve has the feature of double-sealing performance. The installation direction should refer to the arrow on the valve body, which indicates the medium flow direction, when control the flow of medium in single direction.

l Installation of flange connecting valve is on diagram. Lock down the connecting bolt after add sealing washer.

l Synthetic performance of the valve must be done after adjust is over: turn on the power and open the valve, the stroke control device should cut down the power exactly when the valve is in the state of full open or full close. While the torque limit device is in critical state. The open angle indicating device should display the open state of the valve gate exactly.

運(yun)輸及保管:

Transportation and protection

l 運輸時(shi)應避免撞擊蝶閥(fa)及傳動裝置,閥門(mén)應處于全閉位置(zhi),以防在運輸中密(mi)封面和傳動部件(jian)損壞。

l 當閥門水平(píng)放置運輸時,傳動(dòng)裝置及傳動部位(wèi)應懸空,以防止傳(chuan)動軸受力過大而(ér)變形損壞。

l Transmission device and part should be hung up when the valve is in horizontal in order to prevent damage of driving axle.

l The valve should be stored in dry room. It should be in full close state when long stored. Add lubrication to the transmission part and the device should be dampproof and dustproof.

維護及(ji)檢修:

Maintenance and examination

l 定期檢查傳(chuan)動裝置的運行情(qíng)況:電機部分、控制(zhì)開關是否🥵異常。

l 定(dìng)期給閥的傳動部(bu)位加潤滑油。

l 定期(qī)檢查閥的密封填(tian)料處,補充、更換填(tian)料以防介✂️質🐆外洩(xie)。

l 對閥門周期性維(wei)護時應全面檢查(chá)閥的各密封部💜位(wei)💰、傳☔動🔅部位,對各密(mì)封部位應進行檢(jian)測,對檢測數據應(ying)記錄在案。

l Check the working condition of electric parts, control switch and sealing of pneumatic device regularly.

l Add lubricant to the transmission parts regularly.

l Check the sealing filler of the valve regularly. Complement or change filler avoiding leakage of medium.

訂貨須(xu)知:

Information for order

l 選用訂貨時,請(qing)參照産品樣本注(zhù)明産品規格、型号(hào)㊙️、客☁️戶選用執行器(qi)代号及技術參數(shù)(使用溫度、設備工(gōng)況、介質性質等)。

l Please indicate the type, model and technical parameter (using temperature, working condition of equipment and characteristic of medium etc) referring to the product sample when you place an order.

l If you don’t indicate actuator code selected by user when you place an order, we will select the basic collocation of our company for you. The basic type is a normal type without any special request and corresponding accessory. The basic transmission device and electricity device is normal type. If you have especial demand (anti-explosion, outdoors and micro control etc), please indicate in the contract.

l If you have other special demand, need special medium or the data that is not listed in the table, please contact with our department of market and technology. We can design and manufacture for you especially.